Magni will make its official debut on the small fixed telescopic handler market at the Intermat show, in Paris.

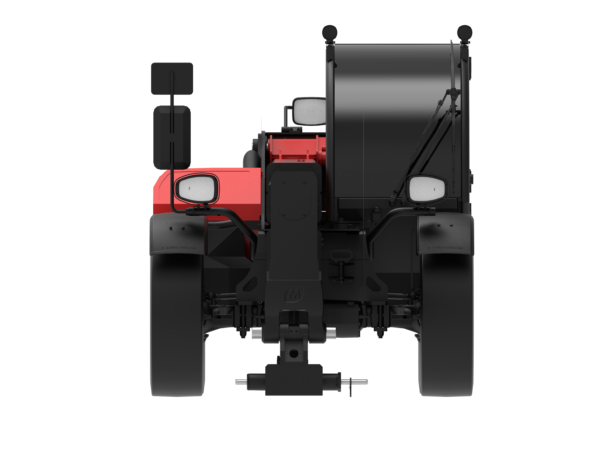

Magni will make its official debut on the small fixed telescopic handler market at the Intermat show in Paris from 24 to 27 April 2024. In fact, the event will mark the presentation of the new Magni TH 3.6, the most compact machine the Castelfranco Emilia brand has ever produced. With a load capacity of 3 tonnes (6613 pounds) and a maximum height of 5.9 metres (193 feet), it is intended for the construction industry and for all contexts, such as logistics, which require small size but still demand excellent performance and innovation. This model may also be adapted to create a version for agriculture in the future.

Its low-level design makes the TH 3.6 perfect for working in the tightest spaces and facilitates its transportation both on trucks and in containers. Ground clearance is still optimal, enabling operation even on the harshest, most uneven terrains. Available with Stage IIIA and Stage V engine of 55 kW (75 HP), it has a top speed of 35 km/h. The four-wheel drive guarantees unrivalled stability in all jobs, while the four-wheel steering system offers three steering modes: front, round and crab. What’s more, the electronic hydrostatic transmission ensures outstanding performance, unbeatable traction and excellent grip even off- road.

The cab, intended to maximise the performance of the new chassis, is designed to meet all needs, with superlative convenience, safety and comfort. The operator enjoys full visibility thanks to a large windscreen which extends from their head to their feet, allowing them to view the load even when completely lowered or suspended. The cab is ROPS/Level 2 FOPS certified and equipped with an upper protection grille to guarantee operator safety even during the most delicate operations. What’s more, the pressurised interior provides a safe working environment in all working conditions. The driving seat delivers outstanding comfort and ergonomics, as the steering column can be set vertically for even more convenient access to the cab, while the seat can be moved forwards and backwards for an optimal driving position.The aeration system filters all incoming air to protect the operator from pollution.

Consulted via 7 inch touch screen, the Magni Combi Touch System (MCTS) on-board software provides complete control of the machine for a smooth, pleasant user experience, with icon-based navigation. From the main menu, the operator can access the themed screens with the various functions offered on all TH machines, including load charts. Unlike competitor models on the market, which have the usual load cell systems, the TH 3.6 will be equipped with a more sophisticated, precise tipping protection system, to maximise performance and safety. This is the “Load Moment Indicator” (LMI) system, available on the entire Magni telescopic handler range, which enables constant monitoring of the machine’s movements to prevent any kind of overload. If the system detects operating anomalies, it disables all movements which may aggravate the situation and only allows actions which can be performed in safety. With this new product, Magni TH applies its expertise to a previously unexplored segment, without

sacrificing the key principles underlying its telescopic handlers’ success.

At Intermat 2024, Magni TH has also scheduled the market launch of its new RTH 6.31 model, equipped as standard with ROPS/Level 2 FOPS elevating cab, also available for the RTH 6.22, 6.26 and 8.27 versions. The cab, mounted on a mobile hydraulic support, will be able to rise by up to 1.5 m and acquire a further degree of freedom with inclination from 0° to 15°. This new feature aims to further improve visibility and safety in all contexts which require extremely high precision and monitoring of the handled load, such as jobs using the tree-cutting attachment.