HALL A6.439

At SSAB, we are convinced that good environmental stewardship also drives good business. We are firmly committed to reducing our own carbon footprint and that of our customers. We take action in many different ways – as a signatory to the UN Global Compact, through our membership in environmental research projects and organizations, and by improving our own manufacturing processes, procedures and policies.

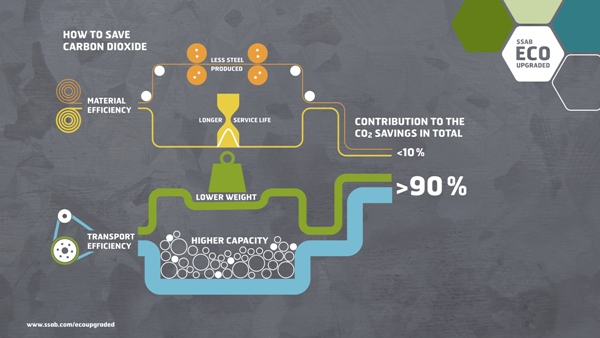

But perhaps our most important effort stems from collaborating with customers. With our SSAB EcoUpgraded program, customers can upgrade to high-strength steel and reduce the weight of their equipment, improve fuel economy and extend product lifetime – all factors that have a major impact on reducing their carbon footprint.

Building muscle – while staying lean, mean and green

When customers upgrade from standard steel to high-strength steel, they can cut the weight of the end product while maintaining the same strength and increasing durability and productivity. From a lifecycle perspective, this is crucial because most of the negative environmental impact comes from a product’s use phase.

And because high-strength steel is stronger than conventional mild steel, less steel is needed to manufacture the product. This also reduces CO₂ emissions. An SSAB EcoUpgraded product will generate CO₂ savings that exceed the CO₂ emitted during the production of the upgraded part. The amount of the savings varies depending on the design and whether or not it is weight-critical. SSAB looks at each specific application and compares the potential CO₂ savings in the use phase to the CO₂ emitted during production. This way, we identify products that would benefit the most from an upgrade to high-strength Strenx® performance steel and/or Hardox® wear plate. Once the CO₂ payback time is reached, the vehicle will continue to deliver CO₂ savings far in excess of the original CO₂ debt.

Rock-solid benefits

- Here’s how high-strength steels from SSAB benefit both the environment and our customers’ businesses.

- Thinner dimensions of steel can be used without compromising on strength

- Fewer resources used in the manufacture of SSAB EcoUpgraded components and vehicles

- Less fuel needed for the same work – haul the same load in fewer number of trips

- Lower carbon dioxide emissions over entire lifecycle

- Meet and stay ahead of tougher environmental requirements and legislation

- OEMs can enhance their environmental profile and gain a competitive edge

From good to great: A customer success story

Successful projects and satisfied customers bear witness to the success of EcoUpgraded on many levels. For one customer, an ultra-light tipper chassis used 610 kg of Strenx® 960MC Plus to replace 750 kg of S700MC steel. And in the body, 830 kg of Hardox® 500 Tuf replaced 1,000 kg of Hardox® 450.

This brought a total weight reduction of 18% for the upgraded parts. The body’s lifetime was doubled, to 12 years, eliminating the need to change the body on this chassis. And the weight was reduced by 310 kg, which increased the load capacity by the same amount.