This year, Austrian recycling pioneer Lindner is highlighting once more the importance of the Circular Economy. Over its many decades, Lindner has developed, produced and installed countless shredders and system solutions – both mobile and stationary – to efficiently process various waste streams. Now more than ever, the focus is on energy efficiency, productivity and the economically viable transformation of the old into new – and this includes plastics, as well as waste wood recycling, and the production of high-calorific solid recovered fuels. The innovative technology for this is developed in-house, by Lindner’s R&D team with its decades of experience, yet Lindner’s customers also benefit from its many cooperative research projects. One of these is the lead project, circPLAST-mr, carried out in partnership with universities and other industry leaders to find new solutions for mechanical recycling.

Be A Waste Transformer

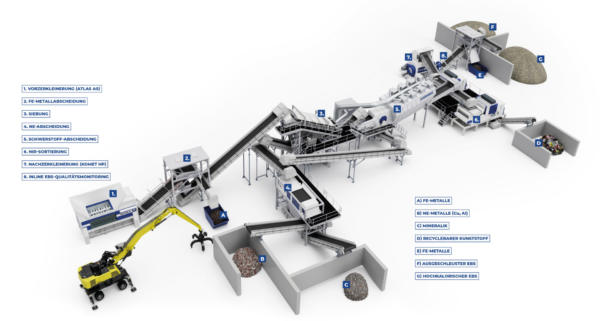

Is Lindner’s call, but also its promise to the entire waste and recycling industry at the IFAT 2022. In recent years, recycling has become increasingly important, both socially and politically. The EU’s Green Deal, specifying recycling quotas, and the drive to keep secondary raw materials in the cycle for as long as possible are shaping the waste management industry just as much as the shortage of skilled workers, rising energy costs, and the demand for higher productivity – challenges that Lindner’s team face with enthusiasm. Dedicated to recycling, Lindner not only offers individual but also comprehensive system solutions, which make it possible to separate potential raw materials as efficiently as possible from various waste streams, such as municipal, commercial or industrial waste. At the same time, the non-recyclable material is transformed into another valuable raw material – medium- and high-calorific substitute fuel – in the post-shredding process and with the additional use of quality monitoring.

From Waste Disposal to Resource Recovery

A smart concept can transform a company from a waste collector to a recycler, thanks to the many possibilities of waste processing. The more potential raw materials can be extracted from the material flow, the better the economic balance. Especially with regard to the recovered plastics, more and more waste processors are recognising the additional value that can be created. Together with its subsidiary Lindner Washtech, Lindner has been operating successfully in this segment worldwide for many years. The cornerstone for successful plastics recycling is above all the perfect coordination of the four process steps: Shredding, sorting, washing and drying. In this way, it is possible to install comprehensive plants – to date, more than 200 plastics recycling plants have been put into operation – to recycle various plastics such as PE-LLD films, PE-HD bottles, PP household goods and PET bottles. In addition to numerous international companies, Europe’s first independent research centre, the NTCP (National Test Centre Circular Plastics), has also chosen Lindner lines (more information: https://www.lindner.com/ntcp-modular-washing-system).

circPLAST-mr – Lead project for mechanical plastics recycling

Under the project management of the Johannes Kepler University (JKU) Linz, eleven scientific and fourteen well-known company partners, most of them market leaders in their segment, including Lindner, are working on how to obtain high-quality recyclates from used plastics. For the first time, experts from all areas of plastics recycling have been brought together to make the best possible use of possible synergies. In total, the research program is divided into seven work packages (WP): Material flow preparation I (collection and pre-sorting), material flow preparation II (shredding, sorting, washing), data management & digitalisation and LCA-oriented process design. Lindner has taken the industrial lead in the material flow processing work package and is sitting at the table there together with Alpla, the world market leader for plastic packaging, in order to be able to sort and clean packaging even better. The latest technological innovations are used here, which are not yet available on the market.

In the research project, different tasks are being investigated, such as what influence the processing quality has on the sorting quality and which technologies are most effective here – single or twin-shaft shredders – and how must the shredder communicate with the sorting unit. These and other questions, from shredding to washing and drying, are being researched in several test series, thus further expanding the knowledge in each of these segments and better coordinating all interfaces. In this way, it should be possible to optimise plastics recycling significantlyand also optimally adapt Lindner’s solutions to the market and customer needs.