- Liebherr wins the Bauma 2025 innovation award in the category ‘Digitalisation’

- The winning product was the autonomous system ‘Liebherr Autonomous Operations’

- A total of three Liebherr products made it into the final 15

Liebherr is bringing some 100 or so exhibits to Bauma 2025, to be displayed to the public on an exhibition space spanning more than 15,000 square metres. To kick off proceedings for the exhibition, the evening before the doors opened was marked with a ceremony to present the innovation award. The innovation award honours groundbreaking developments across five categories in the construction, construction material and construction machine industry. 2025 sees the coveted prize awarded for a 14th time. Liebherr was among those taking part and was presented with the innovation award for the category ‘Digitalisation’ at the awards ceremony. The product crowned the winner was none other than ‘Liebherr Autonomous Operations’, which is propelling the construction site closer to the future.

Pioneering ideas that enrich the industry and bring us all a step ahead are celebrated at Bauma – the world’s leading exhibition for construction, material handling and mining machinery, construction vehicles and equipment – with the innovation award.

This year, several Liebherr products were among the nominees up for the prize. Over the course of several selection rounds, the list of entries submitted got shorter and shorter until only 15 nominated entries were left for the final round. The prize winners only themselves knew they had won when their name was read out at the evening ceremony. This was held on 6 April 2025 in the International Congress Center of Messe München. The guests looking on included representatives from the worlds of politics, industry and the media, as well as representatives from the nominated companies, including Liebherr. The standard of competition was very high, but Liebherr-Werk Bischofshofen GmbH had every reason to celebrate in the end. The employees accepted the innovation award in the category ‘Digitalisation’ for their product ‘Liebherr Autonomous Operations’ to rapturous applause.

Liebherr Autonomous Operations

Liebherr Autonomous Operations is an autonomous system for wheel loaders from Liebherr-Werk Bischofshofen GmbH and the result of many years of intensive development work. Using the system, the repetitive and monotonous tasks of a wheel loader can be undertaken simply and intuitively without a driver. This helps counteract the difficulty of finding staff for monotonous routine tasks. At the same time, it can create space for employees to focus on more complex activities. In other words, it facilitates fully automated wheel loader operation. The autonomous system gives operators a simple and user-friendly application that does not require any specialist IT knowledge. An added benefit: the autonomous optional extra is developed specifically for use with earthmoving machines and opens up new opportunities for planning jobs and organising working time. Liebherr Autonomous Operations is redefining efficiency and safety in the use of wheel loaders.

Liebherr into the final 15

The application process for the Bauma 2025 innovation award was held months ago, with 208 applicants, including companies and universities, submitting their innovations for consideration. A total of five Liebherr products were nominated, three of which made it all the way to the final. On the evening of the awards ceremony, Liebherr-Werk Bischofshofen GmbH picked up the innovation award for its ‘Liebherr Autonomous Operations’. The ‘Positioning Pilot’ and S1 Vision were also among the finalists:

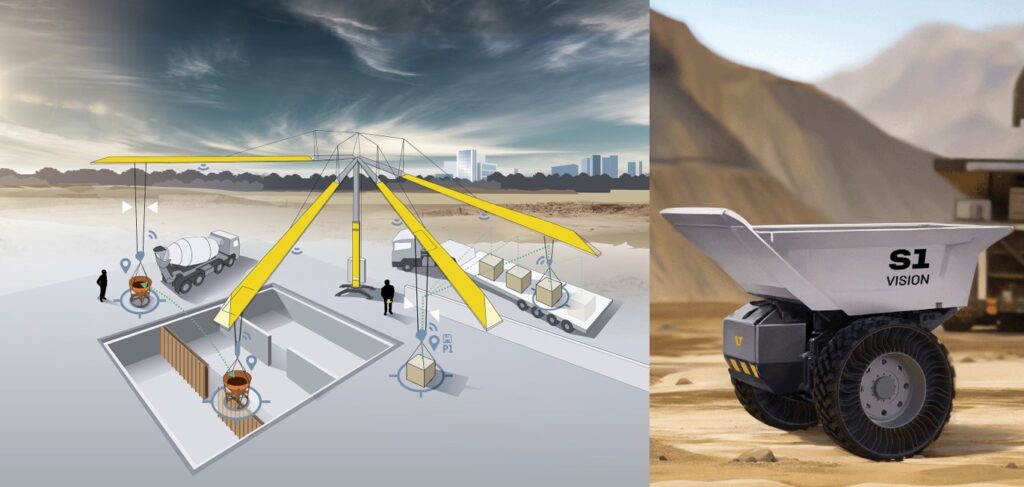

The ‘Positioning Pilot’ driver assistance system is one of the nominees in the ‘Machine Technology’ group and enables semi-automated, sway-free crane operation. The intelligent assistance system enables the crane operator to semi-automatically access several stored hook positions without sway and travel individually mapped routes. Safety on site is also increased through the semi-automatic driving of predefined distances. Plus, the crane operator is freed from repetitive, monotonous lifting tasks. This makes the day-to-day operations on the construction site safer for people and the machinery, and makes work processes more efficient.

The S1 Vision, which was developed by Liebherr Corporate Ventures AG and Liebherr Mining Equipment Newport News Co., was nominated for the innovation award in the ‘Machine Technology’ category. The single-axle truck is born of the vision to reimagine the conventional haulage concept for mining trucks: only the core components that are necessary purely for material transport are used. Despite having just one axle, the product still has a payload of up to 131 tonnes. Because of this flexibility, the S1 Vision can be adapted for various applications, including earthmoving, farming and agriculture, construction and mining.

About the Bauma innovation award

The competition that culminates in the innovation award is a collaborative project headed up by VDMA Construction Equipment and Plant Engineering, Messe München, the German Construction Industry Association (HDB), the Central Association of the German Construction Industry (ZDB) and the German Building Materials Association (bbs).

There are five categories in total, in recognition of exceptional achievements in the construction sector. These achievements help to make work methods, products and processes more eco-friendly, more efficient, safer and more future proof, even in an ever-changing environment. The categories are: climate protection, digitalisation, machine technology, construction and research.

A Liebherr product was also honoured with an award at the last Bauma, three years ago, when Liebherr France SAS won the prize for the climate protection category. Its R 9XX H2 hydrogen crawler excavator was recognised as a groundbreaking step towards a zero-emission construction site.