Liebherr adds theme pavilions to its appearance at Intermat with the approximately 20 exhibits. In the ‘Digitalisation’ pavilion, the Group showcases which technologies and solutions support customers and partners throughout the entire customer journey. The MyLiebherr customer portal combines digital services and solutions, making customers’ work easier. It provides support with the planning, productivity, safety and maintenance of machines and processes. The assistance systems integrated in the machines increase efficiency and productivity and make a significant contribution to the safety and conservation of valuable resources.

Liebherr showcases itself at Intermat with a theme-focused appearance. Theme pavilions on digitalisation, drive technologies and services complement the product show with the around 20 exhibits. With the ‘Digitalisation’ theme, the motto ‘On your site’ highlights that customers and partners with their individual needs are always the top priority, wherever they are, wherever they go. Liebherr understands digitalisation as a future-oriented, far-sighted and strategic approach, which guarantees the highest efficiency as well as trustworthiness through transparent and fair action. Customers and partners are also guided through and supported in their applications and specific challenges throughout the entire customer journey. Digitalisation also plays a key role in driving innovation, utilising new technologies, optimising processes and helping to conserve valuable resources.

Pavilion categories: Planning, Safety, Perfomance and Maintenance

In the ‘Digitalisation’ theme pavilion, visitors discover the comprehensive solutions offered by the Liebherr Group and how these solutions cater to the requirements and individual needs of customers and partners.

- Against this background, the pavilion is divided into the categories of Planning, Safety as well as Performance and Maintenance. These digital solutions enable the collection of relevant construction site and machine data, followed by subsequent analysis and evaluation. This result in better and more reliable machine operation under the category Planning.

- On this basis, proactive and reliable performance and maintenance planning of machines can be carried out. The digital solutions thus improve the efficiency of the machines and processes, and create time as well as cost benefits for customers – Performance and Maintenance. Modern assistance systems and semi-autonomous functions make a significant contribution to working even more safely on the construction site – Safety. They relieve machine operators, provider greater comfort and guarantee simpler work without any worries.

MyLiebherr digital portal

The MyLiebherr digital portal combines digital solutions and services, making them easier to understand for the users.

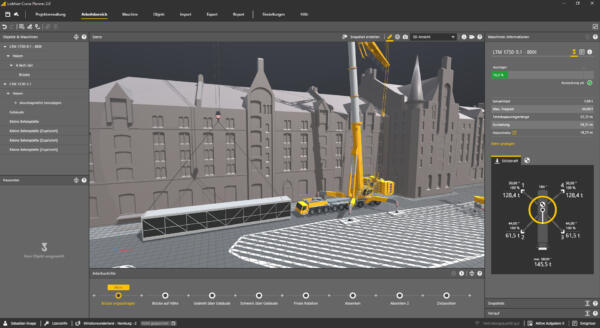

- MyLiebherr plays an important role for the product divisions of the Group and is a common theme in the ‘Digitalisation’ theme pavilion. It includes, for example, planning solutions as well as the Crane Planner application. Or licences for assistance systems can be purchased in MyLiebherr.

- MyJobsite is a digital solution for deep foundation machines. It enables relevant process, machine, construction site and position data to be recorded, displayed, analysed, managed and evaluated. The data collected can be retrieved at any time via a web browser and the customer always has a view of their relevant construction site figures. The consolidated and processed data can be used on a deep foundation machine construction site in a wide variety of subprocesses and for different stakeholders in a targeted manner.

Digital services and numerous benefits which facilitate day-to-day work

The company develops its products together with its customers and partners so that Liebherr can support and simplify their workflows and processes with digital solutions. The Group consistently pursues this customer- and partner-focused approach on several levels. Networked platforms enable cross-manufacturer integration into our customers’ systems and our partners’ business processes.

- The MyLiebherr customer portal makes digital services and solutions easily accessible for users. It includes various applications for the planning, productivity, safety and maintenance of machines and processes. In addition, the portal offers training for skilled workers, telematics solutions, site monitoring and integrated functionalities for current machine information. For example, Liebherr provides modern hub planning software with the Crane Planner 2.0 planning tool for mobile and crawler cranes integrated in MyLiebherr. With this planning tool, crane operations can be planned and visualisations of dimensioning and load capacities can be created, which can be incorporated into the real environment via Google Maps. Exact load capacities, support forces and centre of gravity calculations are displayed in real time. If the telescopic boom length changes, the planning data is recalculated with the new load capacity. The software can also be used to generate visualisations in 3D views. Another advantage: the planning reports can be shown to the end customer without the need for CAD knowledge.

If a confined construction site, projecting edges or strict safety regulations become a challenge during a mobile crane application, the qualification measure to become a digital Mobile Crane Operator supports the mobile crane operator. The solution is the perfect interaction between a good crane and a good crane operator. The basic principles for handling mobile cranes can be completed flexibly and independently in an eLearning module. Users are taught the basic principles of how to handle mobile cranes in 18 units of around 60 minutes each.

Assistance systems for safe application and higher productivity

- Assistance systems such as the Skyview 360° camera system ensure safe handling of construction machines on the construction site. The system with several cameras provides an overview of the machine’s operating environment. It detects potential hazards in good time, thus reducing potential accidents. As a result, work cycles can be completed quicker, more effectively and safely. This saves time and money. At the booth, visitors can take a closer look at the Skyview 360° assistance system in the L 546 wheel loader and the R 924 Generation 8 crawler excavator. Liebherr showcases the R 924 with the semi-automatic machine control system from Leica Geosystems, another assistance system that increases safety during the application.

- The automatic weighing device in the TA 230 Litronic dump truck enhances the performance. For example, the device, which is installed as standard, registers the loaded weight in real time. During the loading process, the current load capacity is shown on the display both numerically and as a simple, recognisable symbol. This gives the driver valuable information on the loading process. At Intermat, Liebherr presents this checkweigher assistance system in its TA 230 dump truck and L 546 wheel loader. Visitors can also find out what advantages the automatic tyre pressure measurement offers. This can be used in both exhibits.

- In the R 972 crawler excavator, the Bucket Fill Assist function ensures higher productivity and greater comfort. The ‘Anti-Stalling’ mode prevents the bucket from jamming when penetrating digging material. In addition, the assistance function enables the semi-automatic filling of the bucket, thus offering an automated and quicker cycle through simpler bucket filling as well as improved penetration of the digging material.

MyJobsite – digital industry solution for deep foundation machines

The MyJobsite digital tool simplifies the documentation of data from a variety of sources and its processing, analysis and translation into relevant information such as performance parameters, construction progress or machine utilisation. Quality control can be carried out on that basis for certain processes on the construction site. This lays the foundations for optimising work processes and ultimately saving time and money. A list of all the work processes can be stored in MyJobsite by means of planning data. In this way, work steps, for example of deep foundation machines, can be processed systematically. Machine and process data can be accessed live and is constantly updated. The user always has an overview of scheduled, active and completed processes, and therefore of the current progress of the construction site. This digital solution has proven its worth, particularly in deep foundation machines with the LRB 23 piling and drilling rig.