Working in a sustainable way means creating value in balance with the environment and people, a balance that technology can facilitate in an absolutely beneficial way, from all points of view. Especially in a historical moment like this, in which global geopolitical problems heavily influence the work of companies.

This is the vision of STADLER Anlagenbau GmbH, the globally active German company specializing in the design, production and assembly of turnkey recycling and sorting plants. Centrality of the human relationship, top-level technology produced 60% internally and a trusted and guaranteed network of suppliers are the ingredients of winning sustainability.

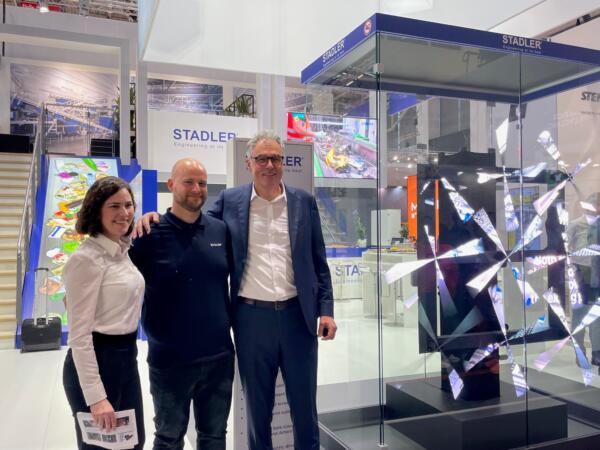

On the sidelines of the press conference presenting the company objectives and the latest product news, during the IFAT fair in Munich, Recover Magazine explored the key themes of Stadler’s strategic development with some exclusive questions.

How influential is technology today for predictive maintenance or with artificial intelligence, and how important are human relationships?

“It is always a combination of both – observes Julia Stadler, Chief Digital Officer since 2023 – Modern technology like vibration and temperature sensors are essential for predictive maintenance. Nevertheless, human relationships will always be crucial for a successful after-sales management. Regular visits of our service engineers permit a detailed analysis of the conditions of a sorting plant”.

A good plant is built from good components. How much is built internally and how is your supply chain developed? In light of recent geopolitical issues do you think there will be changes?

“Our strategy is to build at least 60% of the plant inhouse – explains CEO Willi Stadler – Thereby, we want to ensure a high level of control regarding quality and delivery time. This applies above all for the conveyor technology, ballistic separators, trommel screens, delabelers, electrical control and steel construction. Regarding the remaining 40% we collaborate with a small number of long-standing suppliers or partners. There are specialized companies for shredders, NIR-technology and magnetic systems with whom we work successfully. In view of the geopolitical challenges, it will be more and more important in the future to maintain a reliable supply chain“.

In the interest of consistency, STADLER has a number of sustainability management initiatives in place internally. What are they and how important do you think it is for companies from both an economic and social perspective?

“We have had a sustainability strategy since 2019, which is based on an in-depth materiality analysis – continues Willi Stadler – Besides, we publish our annual sustainability report in accordance with the German Sustainability Code (DNK) and are committed to the 10 principles of the UN Global Compact. Overall, we have broken down our sustainability strategy into initiatives for all our departments, the progress of each initiative is monitored on a regular basis.

All three pillars of sustainability are important to us: economic sustainability, i.e. generating a profit, is crucial to ensure the future viability of the company. We also attach great importance to social aspects, i.e., employee satisfaction and a good working atmosphere, which is the foundation of our company’s success. And of course, we address the environmental pillar, which we are improving continuously, e.g. by reducing the material needed for our machines”.