Recyclates that are barely distinguishable from virgin material – that’s what plastics processing specialist Lindner had in mind when developing the new hot-wash system to be presented at the K 2019 in Düsseldorf. In addition to effective cleaning, the solution offers not only high but above all continuous output

Gone are the days when products made of recycled plastics were a well-intentioned but marginal phenomenon. Markets, and in particular big brands, have to react to the sustainability trend and are demanding ever-higher quality recyclates in ever-increasing quantities. To deliver this high quality, complex processing systems – and here, in particular, washing technology – are needed. One specific challenge is posed by undesirable materials stuck to post-commercial and post-consumer film as well as unpleasant odours. The more effectively these materials can be removed, the higher the quality and the potential revenue.

German-Austrian company Lindner Washtech has developed a three-stage hot-wash system to meet these requirements and also ensure high productivity. Managing Director of Lindner Washtech, Harald Hoffmann: ‘When developing the new components, we focused on effective cleaning and continuous processing so that all preceding and subsequent equipment can be operated productively at all times. That is why we based this solution on our tried-and-tested technology, combined it with the advantages of hot washing and deliberately left out the otherwise common, but often vulnerable, batch processing.’

Three stages to success

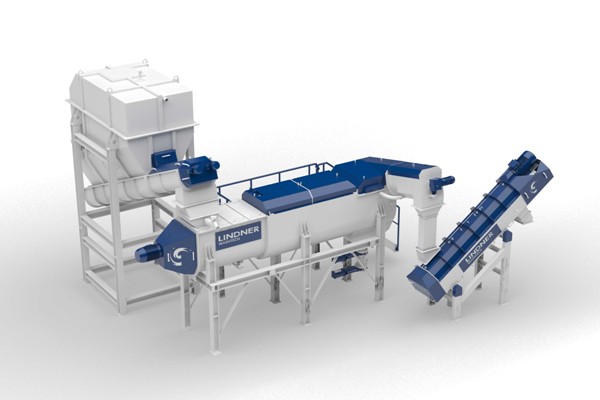

The modular and compact Lindner hot-wash system has three stages and does not require any additional conveyors. In the first stage, the shredded and pre-washed plastics are fed into a reactor, mixed with hot water and washed. Already at this stage, mixing arms apply concentrated friction to the material. The double discharge screw conveyor then feeds the plastics into the new hot-wash rafter in optimally dosed quantities. This is a new and improved version of the already successful rafter pre-washer, in which continuous friction is applied to the material to remove and separate residues effectively and gently. In the third and final stage, the Twister friction washer, a machine specifically designed for this application, removes the hot water or the hot caustic solution. The liquid is then separately treated.

Optionally the system can also be operated with caustic solution to remove even stubborn fat and oil residues, as well as glue. The downstream water treatment system continuously monitors the water’s alkaline content and automatically applies the necessary chemicals.

Alongside Lindner’s modern and robust shredders, the innovative hot-wash system is a key component in Lindner’s new system solutions for plastics recycling.

Lindner at the K 2019

In addition to the indoor booth in hall 9, D78/E75, Lindner Recyclingtech, together with its subsidiary Lindner Washtech, will be exhibiting for the first time this year in the outside area (15.2). A system solution consisting of a shredder and a dry-cleaning system can be seen live in action, recycling plastics twice a day.

About Lindner Washtech GmbH, Großbottwar/Germany www.lindner-washtech.com